Advanced Use: System Design & Technical Diagrams

Get your team started in minutes

Sign up with your work email for seamless collaboration.

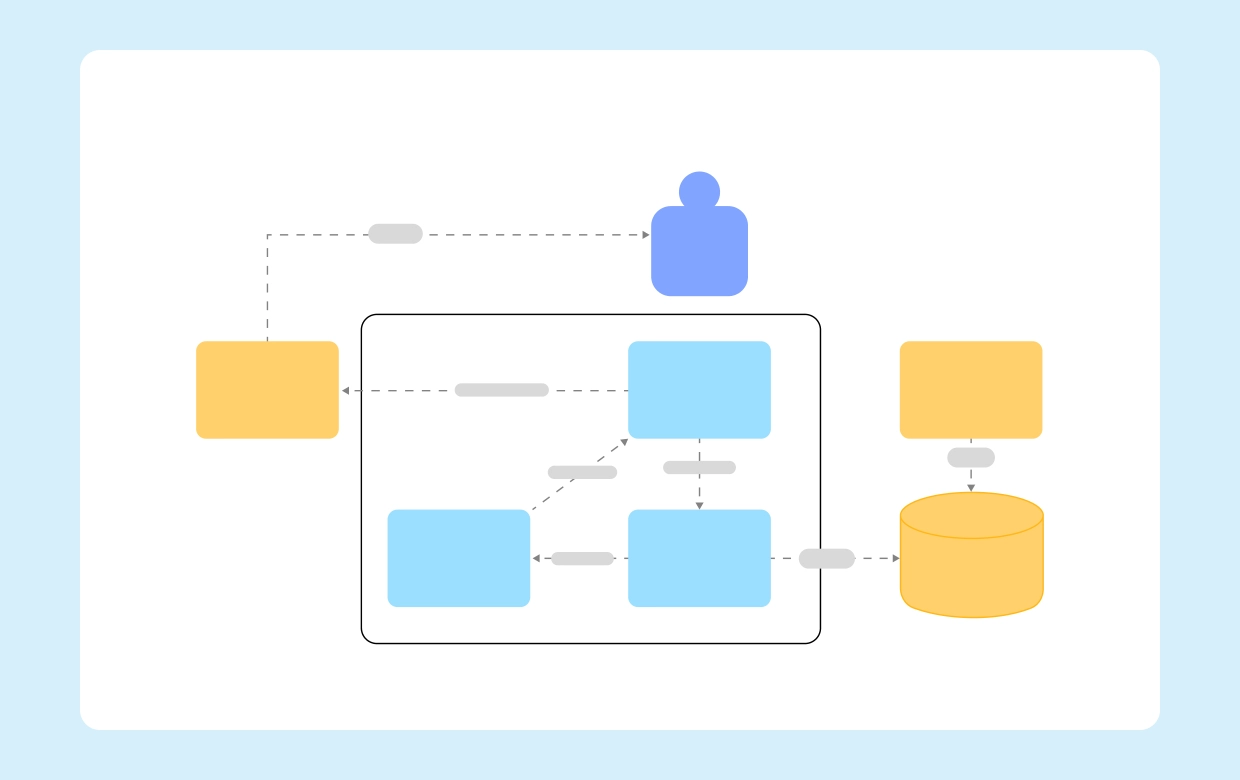

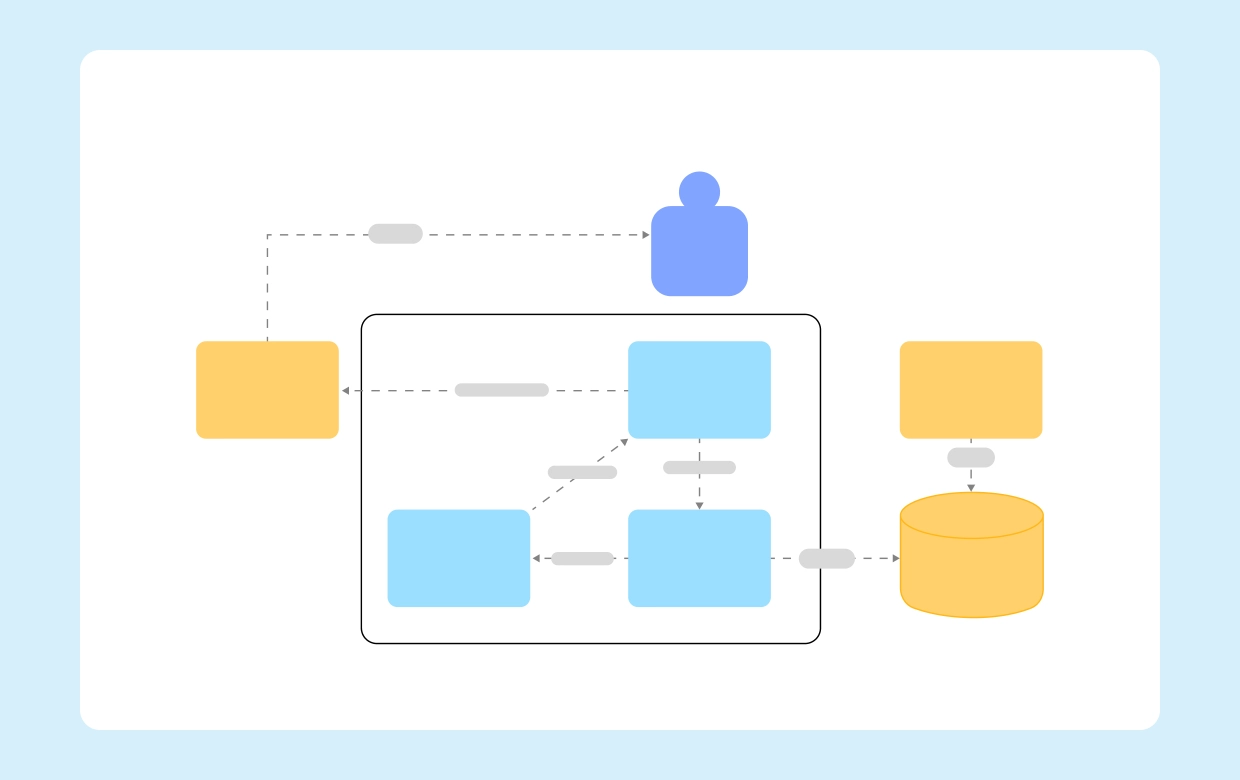

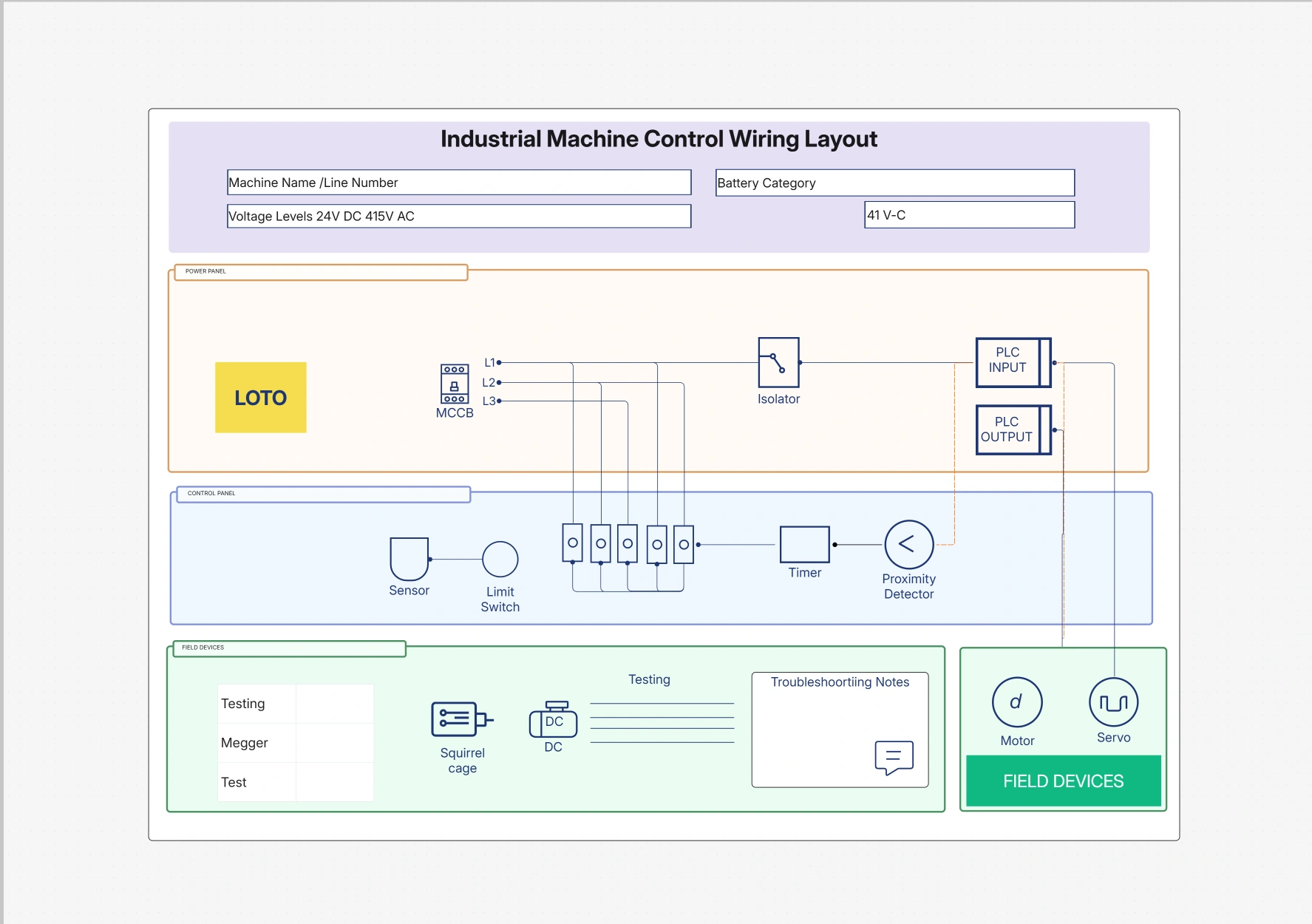

As systems grow more complex, technical diagrams become the single source of truth for design, integration, and review. From cloud architectures to embedded electronics and mechanical assemblies, precise visuals align engineers, stakeholders, and auditors.

This guide covers the advanced use of system design and technical diagrams, showing where each diagram shines, how to build them, and how to keep visuals living alongside specs, tests, and deployments.

Start fast with the Workflow & Process Diagram Maker and explore templates: Schematic, Circuit, Free Body, Technical Drawing Examples, and System Design Process Flow. See the big picture in the Pillar Guide.

Diagrams compress complexity into clear, testable models. They expose integration seams, performance constraints, and failure domains before they become costly incidents.

When paired with documentation and automated checks, diagrams evolve into design contracts communicating intent, enabling code reviews, and guiding verification from prototype to production.

Key advantages:

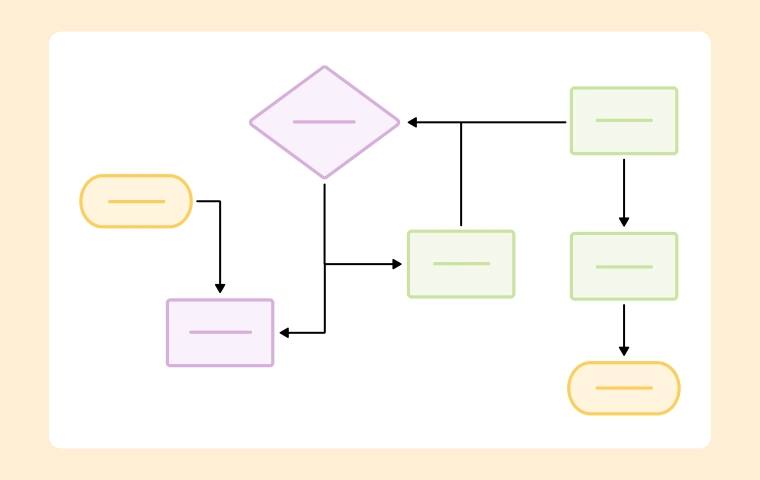

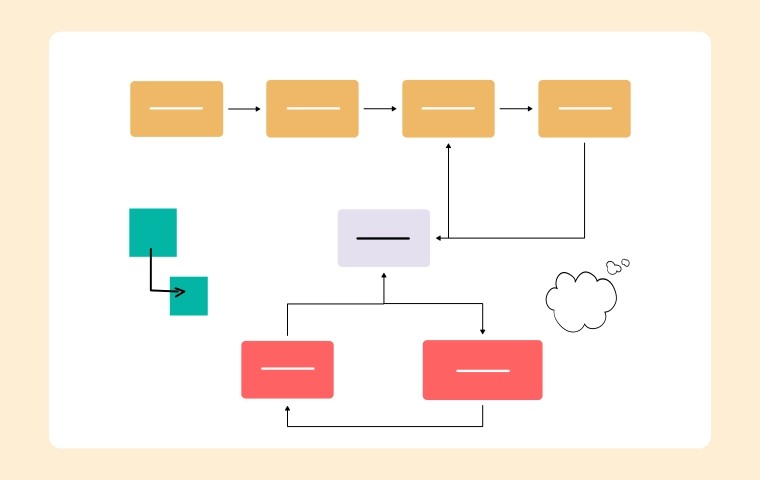

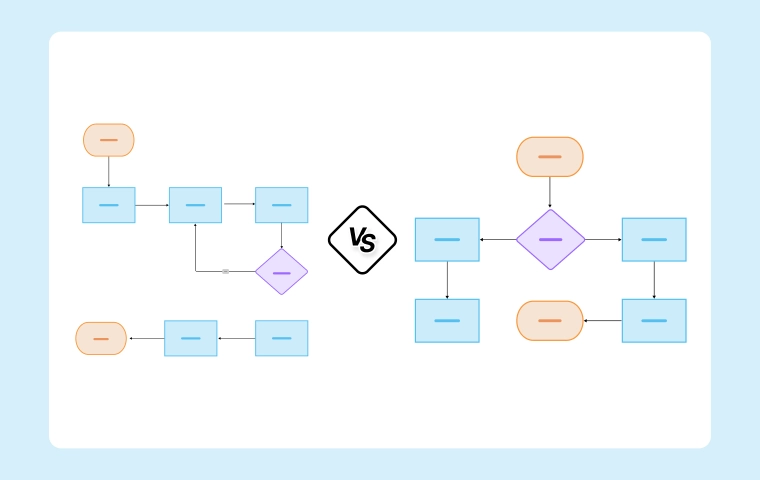

Choose the right visualization to reduce ambiguity and accelerate implementation. Each type complements the others in a full system stack.

Go beyond pretty pictures. Treat diagrams as living specs that drive implementation, testing, and change management across teams.

Make your diagrams authoritative, readable, and easy to maintain throughout the lifecycle.

Do this:

Avoid this:

Advanced system and technical diagrams turn complexity into aligned execution. By choosing the right visual, layering detail, and linking evidence, teams de-risk integration and make reviews faster and more decisive.

Build production-ready visuals with the Workflow & Process Diagram Maker and jumpstart with templates: System Design Process Flow, Schematic, Circuit, Free Body, and Technical Drawing Examples. For foundations, visit the Pillar Guide.

.webp)

When should I choose a schematic vs. a circuit diagram?

How do I keep diagrams in sync with code and hardware?

Can diagrams support automated checks?

What’s the best way to handle multi-discipline systems?

How detailed should I go for stakeholder reviews?

Start using Cloudairy to design diagrams, documents, and workflows instantly. Harness AI to brainstorm, plan, and build—all in one platform.

.webp)